Production - regional and high quality

Development: We develop in-house - from the idea and the first test models to the 3D printed prototype.

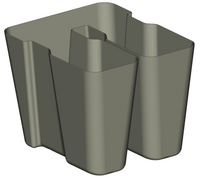

The aspects of “simplicity” and “practicality” are at the forefront and are reflected in the timeless and functional design of the Array-Planter.

Tests with 3D-printed prototypes

Ready for series production: We work together with engineers with experience in the industry to develop products ready for series production.

Durability and recyclability are our top priorities when selecting materials.

Further development into a “product”

Production: The ARRAY-PLANTER is made by injection molding at a facility in the Berlin-Brandenburg region,

Our partner has many years of experience in the field of plastics processing and its modern machines ensure consistently high product quality.